Industrial facilities depend on reliable flow control systems to maintain efficiency, safety, and consistency. Among the many valve solutions available, diaphragm valves have become a preferred choice across manufacturing, pharmaceuticals, food processing, dust collectors, and filtration systems. Their durable design, minimal maintenance requirements, and contamination-free operation make them indispensable.

As a trusted diaphragm valve supplier, Maniks designs high-performance solutions like the TMEP-124 Single Stage Diaphragm Valve, engineered for precision and long-term reliability in demanding environments.

This comprehensive guide explains how diaphragm valves work, where they are used, and why they play such a crucial role in industrial systems.

How Diaphragm Valves Work

A diaphragm valve operates using a flexible diaphragm that moves up or down to control the flow of air, gas, or fluid.

The working principle is simple:

- An electromagnetic coil receives power.

- The plunger and spring mechanism inside the pilot assembly activate.

- The diaphragm lifts or closes, regulating the air or fluid path.

This design results in:

- Smooth flow transitions

- Leakage-free operation

- Longer service life due to fewer moving parts

Maniks’ TMEP-124 series uses a moulded Class-H insulated coil, IP65-protected DIN connectors, and precision-engineered diaphragms for reliability even under harsh operating conditions.

Key Advantages of Diaphragm Valves in Industrial Settings

- Zero Contamination: The diaphragm creates a complete seal between the fluid and mechanical parts, ideal for clean processes.

- High Durability: With fewer components exposed to wear, diaphragm valves deliver long operational life.

- Corrosion Resistance: Available in robust materials that withstand aggressive chemicals and environments.

- Fast Response Time: Crucial for systems like dust collectors, where rapid pulsing improves bag filter performance.

- Low Maintenance: Diaphragm replacement is simple, and the overall mechanism reduces service downtime.

Common Applications of Diaphragm Valves

Diaphragm valves are used in industries that require reliable, contamination-free flow control, such as:

- Dust Collector Systems: Pulse jet bag filters rely on diaphragm valves to deliver consistent air bursts.

- Pharmaceutical Manufacturing: Ensures clean, sterile flow with zero contamination.

- Food & Beverage Processing: Suitable for sanitary, hygienic applications.

- Water Treatment Facilities: Manages flow with precision and long life.

- Chemical Processing: Handles corrosive gases and fluids safely.

The Maniks TMEP-124 valve is widely used in dust collection applications where powerful, consistent pulsing is necessary.

Types of Diaphragm Valves: A Practical Overview

While diaphragm valves come in several configurations, two broad types dominate industrial usage:

1. Weir-Type Diaphragm Valves

- Suitable for throttling

- Ideal for clean, sterile processes

- Limited for viscous or high-solid fluids

2. Straight-Flow Diaphragm Valves

- Full-bore design

- Minimal flow resistance

- Preferred for high-flow applications and pulse jet systems

Maniks primarily provides high-performance diaphragm valves for air pulse systems, optimized for industrial dust collectors.

Material Considerations for Diaphragm Valves

Material choice directly impacts performance and lifespan. Key considerations include:

- Temperature Resistance: Manik’s valves operate in a range of -20°C to 85°C, making them suitable for demanding environments.

- Chemical Compatibility: Elastomers and diaphragms must withstand process media.

- Electrical Safety: The TMEP-124 coil features Class-H insulation and IP65 protection for industrial electrical safety.

- Pressure & Flow Demands: Materials must support high-pressure pulsing applications.

Maniks selects only high-quality materials to ensure reliability in dusty, corrosive, or high-temperature environments.

Maintenance & Troubleshooting Tips for Diaphragm Valves

Even though diaphragm valves are low-maintenance, their efficiency improves with routine checks.

Tips for smooth operation:

- Inspect diaphragms periodically for wear or cracks

- Ensure coil voltage matches the system supply

- Verify DIN connectors are tightly sealed (IP65 standard)

- Check for blockages in pilot holes

- Confirm springs and plunger assemblies move freely

- Replace O-rings when necessary

A well-maintained diaphragm valve ensures stronger pulses, reduced compressor load, and longer bag life.

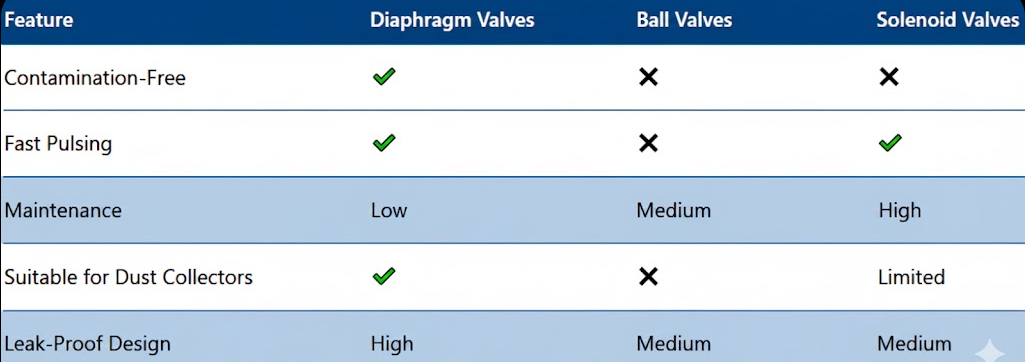

Comparing Diaphragm Valves to Other Valve Types

For pulse jet cleaning systems, diaphragm valves overwhelmingly outperform others due to speed, life cycle, and seal strength.

Innovations & Trends in Diaphragm Valve Technology

Modern diaphragm valves are evolving with smarter, more efficient solutions such as:

- High-efficiency coils reducing power consumption

- Long-life diaphragms for higher pulse cycles

- Improved elastomer technologies for heat and chemical resistance

- Optimized internal design for stronger pulse output

- Digital monitoring systems to track valve health

Maniks continues innovating in this space to deliver higher reliability and longer lifecycle performance.

Why Are We The Trusted Diaphragm Valve Supplier?

The TMEP-124 diaphragm valve reflects Maniks’ engineering excellence with:

Electrical Specifications

- Moulded Coil

- Class-H Insulation

- DIN 209S PG9 Socket (Elcom Make)

- IP65 Protection

- Temperature Range: −20°C to 85°C

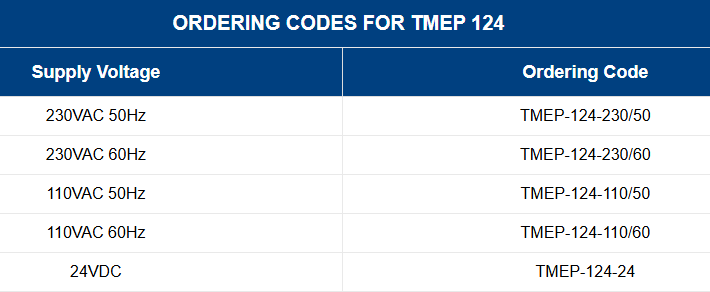

- 230VAC / 110VAC / 24VDC options

- Power: 19VA / 20W

Ordering Codes

These valves are engineered for long-term industrial use with consistently strong output.

Conclusion: Enhancing Industrial Efficiency with Diaphragm Valves

Diaphragm valves are essential components in modern industrial systems, delivering reliability, clean operation, and high efficiency. Whether used in dust collectors, chemical plants, or processing units, they ensure stable flow control and long equipment life.

As a leading diaphragm valve supplier, Maniks provides advanced solutions like the TMEP-124, known for precision engineering, long-term durability, and consistent performance.

If your application requires reliable pulsing, contamination-free flow control, and durable construction, diaphragm valves from Maniks are the ideal choice.